HOME :: Isolation & Ultra Isolation Transformer

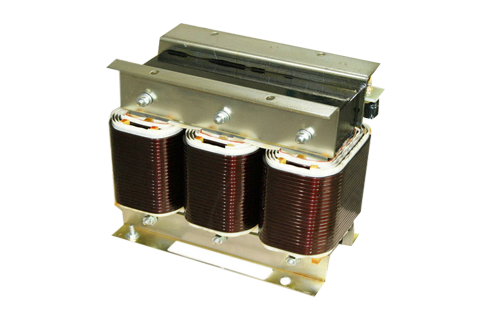

Isolation & Ultra Isolation Transformer

Our Isolation Transformers isolate the equipments from noisy power line hence providing a better option to clients. These remove power line noise, surges, spikes and transients. It also provides high insulation resistance and provides complete electromagnetic and electrostatic shielding.

Our range of Isolation Transformers is designed as per the international standards which give an assurance to the customer on the high quality of the product. An isolation transformer does not have a direct electrical path from the power input side to the power output side. The term is also used to define how much electrical isolation exists between the input and output windings. For example when using line-voltage input transformers to power low voltage device handled by humans, a high degree of isolation is required for safety. Isolated transformers often use separate bobbins for the primary and secondary coil windings, but usually the windings are just wound on top of each other with insulation in between. There is usually an electrostatic shield between windings which is tied to transformer case.

| SL No. | Phase | Single Phase |

|---|---|---|

| 1. | Input Voltage | 220 Volts |

| 2. | Output Voltage | 220 Volts |

| 3. | Transformer Ratio | 1:1 |

| 4. | Power Factor | 0.75 Lag to lead |

| 5. | Frequency | 50 Hz |

| 6. | VI Electric strength | 1500 V AC for 120 sec. |

| 7. | Insulation esistance | More Than 100M Ohms. |

| 8. | Capacitance Coupling | 0.01 PF 100 db |

| 9. | Common Mode attenuation | 100 db |

| 10. | Class Of Insulation | Class 'F' |

| 11. | Losses | 5% |

| 12. | Ambient emperature | 0-50o C |

| 13. | Duty Cycle | Continuous |

| 14. | Lamination | Cargo |

| 15. | Construction | as per IS :2026 |